From Predictive Maintenance to Automation: The Role of AI in Smart Manufacturing

Mar 04, 2025

The manufacturing industry is undergoing a massive transformation, driven by AI-powered smart manufacturing. What was once a sector dominated by manual labor and traditional automation is now evolving into a connected, intelligent, and autonomous ecosystem. AI plays a central role in this transformation, optimizing processes, reducing downtime, and improving overall efficiency.

From predictive maintenance that prevents costly breakdowns to fully automated production lines, AI is helping manufacturers reduce operational costs, enhance product quality, and meet growing market demands efficiently.

How exactly does AI fit into smart manufacturing? What are the practical benefits for businesses adopting these innovations?

This guide explores how AI is shaping smart manufacturing, from predictive maintenance to automation. You will learn how AI-driven systems improve efficiency, reduce costs, and enhance quality. Whether you are in the industry or just curious about the future of manufacturing, this guide will give you a clear understanding of what is happening and what is next.

What is Smart Manufacturing?

Before diving into AI’s role, let’s define smart manufacturing. At its core, smart manufacturing integrates digital technologies like IoT, AI, big data, and cloud computing to improve efficiency and flexibility in production.

Unlike traditional manufacturing, which relies on manual labor and rigid workflows, smart manufacturing integrates real-time data, machine learning, and automation to create a more adaptive and efficient production environment.

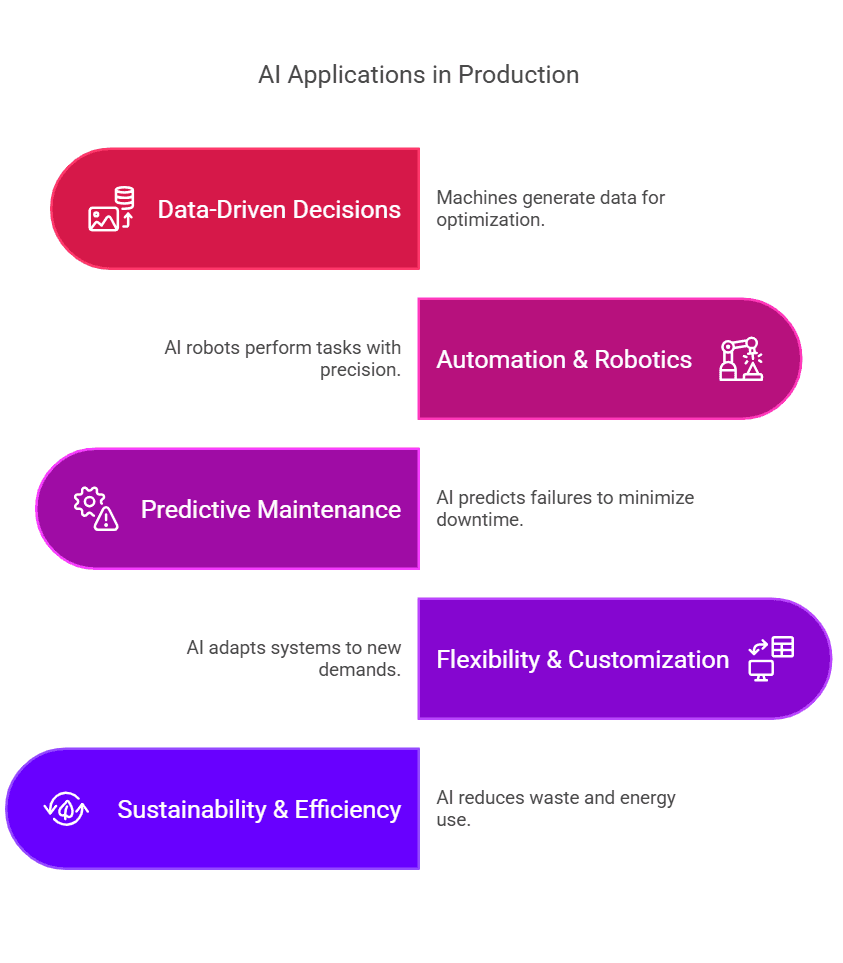

Key Characteristics of Smart Manufacturing

- Data-Driven Decision Making: Machines and sensors generate vast amounts of data that AI processes to optimize production.

- Automation & Robotics: AI-driven robots perform repetitive and complex tasks with precision.

- Predictive Maintenance: AI anticipates equipment failures before they happen, reducing downtime.

- Flexibility & Customization: AI-powered systems adapt to new production demands quickly.

- Sustainability & Efficiency: AI optimizes resource usage, reducing waste and energy consumption.

Now, let’s explore how AI enhances these aspects in real-world manufacturing.

Why AI is Transforming Smart Manufacturing

Artificial intelligence is reshaping manufacturing by offering intelligent automation, predictive insights, and data-driven decision-making. With AI, manufacturers can optimize production processes, minimize waste, and improve overall operational efficiency. Unlike traditional automation, which follows predefined rules, AI systems learn from real-time data, making them adaptive and capable of handling unpredictable scenarios. This ability makes AI an essential tool in modern manufacturing, ensuring resilience in the face of evolving market demands and supply chain complexities.

The adoption of AI in manufacturing is not simply about upgrading technology, it represents a fundamental shift in how production lines operate. Manufacturers are now leveraging AI-powered solutions to enhance accuracy, reduce errors, and introduce self-learning systems that continuously improve. AI is no longer an emerging trend; it is becoming a necessity for companies looking to maintain a competitive advantage in the industry. By integrating AI into various aspects of the manufacturing process, businesses can make real-time adjustments, ensuring they operate at peak efficiency.

AI in Smart Manufacturing: A Game-Changer

AI is the driving force behind smart manufacturing, enabling machines to analyze data, make decisions, and even learn from past experiences. Here is how AI is revolutionizing the industry:

1. Predictive Maintenance: Reducing Downtime and Costs

The Problem with Traditional Maintenance Approaches

Traditional maintenance strategies typically follow two outdated models:

- Scheduled Maintenance: Machines are serviced at fixed intervals, regardless of their actual condition. While this prevents some failures, it often results in unnecessary downtime and wasted resources.

- Reactive Maintenance: Repairs are made only after a failure occurs, causing unexpected breakdowns and high costs.

How AI Enables Predictive Maintenance

AI-powered predictive maintenance analyzes real-time data from IoT sensors, detecting warning signs before failures occur.

Key Technologies Driving Predictive Maintenance

- Machine Learning Models: AI analyzes historical performance data to detect patterns that indicate potential failures.

- IoT Sensors: These sensors monitor temperature, vibration, and pressure in real-time.

- Digital Twins: These are virtual replicas of physical machines, allowing AI to simulate different operating conditions and predict failures.

By integrating AI into smart manufacturing, businesses can avoid costly breakdowns, improve machine longevity, and ensure seamless operations.

2. AI-Powered Quality Control: Improving Product Precision

How AI Transforms Quality Control

AI-powered computer vision and deep learning algorithms analyze products with near-perfect precision.

AI Technologies for Quality Control

- Computer Vision: Uses high-resolution cameras and AI algorithms to inspect products at high speed.

- Deep Learning Algorithms: AI learns from past defects to improve its ability to detect issues in real-time.

3. AI-Driven Robotics: The Heart of Automation

AI-powered robotics learn and adapt, making manufacturing processes more efficient.

Types of AI-Driven Robotics in Manufacturing

- Collaborative Robots (Cobots): Assist humans in tasks like welding and assembly.

- Autonomous Mobile Robots (AMRs): Transport goods across factory floors independently.

4. AI-Driven Supply Chain Optimization

How AI Enhances Supply Chain Management

- Demand Forecasting: AI predicts customer demand, preventing overproduction or shortages.

- Inventory Management: AI monitors stock levels in real-time.

- Logistics Optimization: AI determines the fastest and most cost-effective shipping routes.

5. Benefits and Challenges of AI in Smart Manufacturing

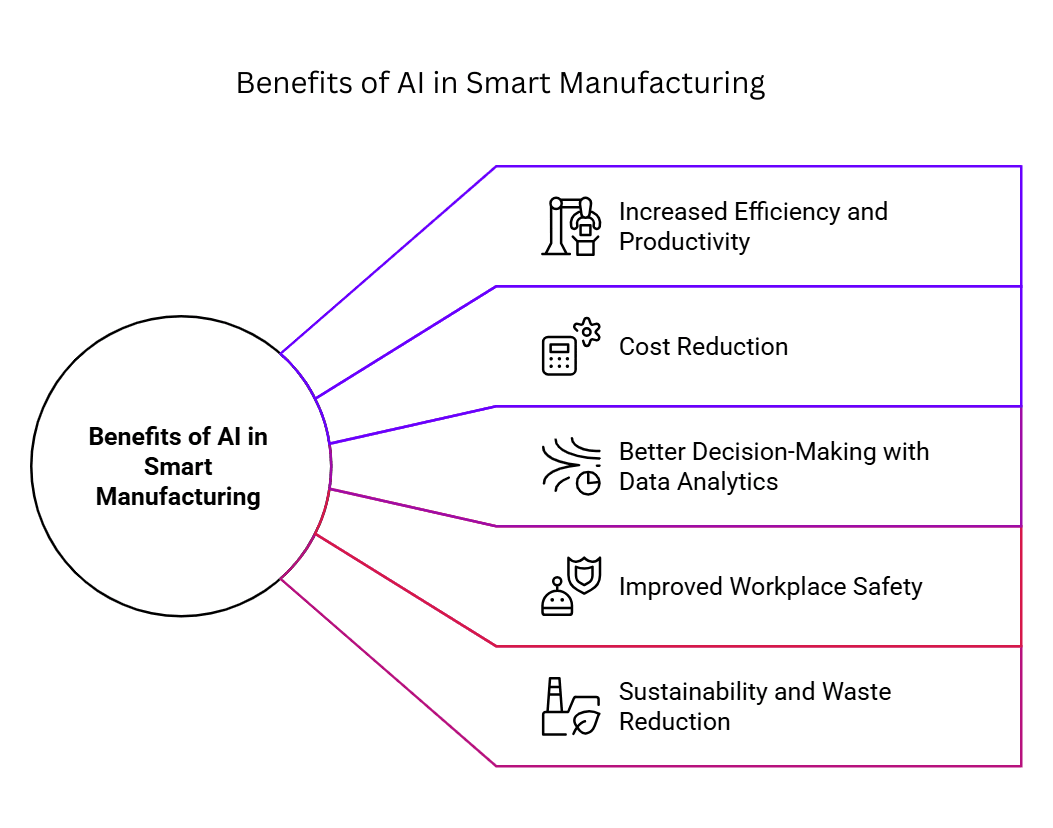

Benefits of AI in Smart Manufacturing

1. Increased Efficiency and Productivity

- AI automates repetitive tasks, allowing human workers to focus on higher-level responsibilities.

- AI-driven robotics and predictive analytics improve workflow, reducing downtime.

2. Cost Reduction

- Predictive maintenance lowers repair costs and minimizes unplanned downtime.

- AI-powered quality control reduces product defects, preventing waste and recalls.

3. Better Decision-Making with Data Analytics

- AI analyzes massive datasets in real-time, offering insights for optimized production planning.

- AI-powered demand forecasting helps avoid overproduction, reducing storage costs.

4. Improved Workplace Safety

- AI-driven robots and cobots handle dangerous tasks, reducing risks for human workers.

- AI-powered monitoring detects safety hazards before they cause accidents.

5. Sustainability and Waste Reduction

- AI helps reduce energy consumption and material waste.

- Smart manufacturing AI ensures optimal resource utilization, leading to environmentally friendly production.

Challenges of AI in Smart Manufacturing

Challenges of AI in Smart Manufacturing

1. High Initial Investment Costs

- Implementing AI-powered robots, IoT sensors, and software requires significant upfront investment.

- Small and medium manufacturers may struggle to afford AI adoption.

2. Need for Skilled Workforce

- AI systems require expertise in machine learning, robotics, and data analysis.

- Manufacturers must train employees or hire AI specialists, which can be costly.

3. Data Security and Privacy Concerns

- AI relies on large amounts of real-time data, increasing the risk of cyber threats.

- Ensuring secure data storage and compliance with regulations is crucial.

4. Integration with Existing Systems

- Many manufacturers use outdated legacy systems that are not AI-compatible.

- AI adoption often requires expensive system upgrades or replacements.

5. Ethical and Regulatory Challenges

- AI-based automation raises concerns about job displacement.

- Compliance with regulations on AI safety, worker protection, and ethical AI use is essential.

The Future of AI in Smart Manufacturing

AI-driven smart manufacturing is evolving rapidly, shaping the future of production through hyper-automation, self-learning systems, and sustainable manufacturing. AI will soon manage entire factories with minimal human intervention, continuously optimizing processes and reducing waste, energy consumption, and carbon footprints.

Currently, AI adoption in manufacturing is steadily increasing, but many companies are still in the early stages, experimenting with pilot projects and limited applications. As AI technology matures, integration will become more seamless, driving innovation and competitiveness.

Looking ahead, AI will play a crucial role in fully autonomous factories, where machines communicate and make real-time decisions with minimal human oversight. The rise of AI-powered digital twins will enhance predictive analytics, allowing manufacturers to simulate and optimize production scenarios before implementation. Generative AI will further accelerate product design and development, enabling faster innovation.

Despite concerns about automation replacing human workers, AI will serve as an augmentation tool, improving decision-making and automating tedious or hazardous tasks. This human-machine collaboration will lead to a more efficient, safer, and highly adaptable workforce, ensuring that AI enhances, not replaces, human expertise in manufacturing.

As AI continues to evolve, embracing these advancements will be key to staying ahead in the competitive landscape of smart manufacturing.

Conclusion

AI is no longer a futuristic concept; it has become an integral component of smart manufacturing. From predictive maintenance that minimizes unplanned downtime to AI-driven robotics and intelligent automation, AI is transforming manufacturing operations by optimizing costs, increasing production efficiency, and improving product quality. By leveraging real-time data analytics and machine learning algorithms, AI-driven systems enable faster and more accurate decision-making, enhancing adaptability to evolving market demands.

Despite challenges such as high initial investment and workforce adaptation, the strategic implementation of AI-driven solutions offers a substantial return on investment, ensuring long-term operational resilience and competitiveness. Companies that adopt AI now will position themselves at the forefront of industrial innovation, while those that delay risk inefficiencies and missed opportunities in a rapidly evolving market.

Are you ready to embrace AI-driven smart manufacturing? Now is the time to act.

Monika Gjorgjievska

Book a Free Consultation

Trusted by leading businesses worldwide

Book a Free Consultation

You may also like

Towards Perfect ES Query Generation with Elastic-builder

Apr 09, 2020

Velimir Graorkoski

Elastic Builder To The Rescue

Apr 22, 2020

Velimir Graorkoski

Understanding the Most Effective Practices of Remote Working

May 19, 2020

Tanja Zlatanovska