10 ways that AI can transform manufacturing processes.

May 22, 2024

Artificial intelligence is more than just a buzzword. It’s a groundbreaking force in today’s technological landscape. In the last 5 years, powerful AI models and technologies have come to transform the way companies in all industries run operations, develop products, and interact with customers.

For the manufacturing industry, AI represents the gateway to smart manufacturing, driving the 4th Industrial Revolution through the adoption of advanced technologies, automation, and the upskilling and reskilling of the workforce.

In this blog, we explore key drivers for AI’s application in manufacturing and examine its real-world use cases and its potential for the future.

Let’s dive in.

Key takeaways

- The core components of AI include machine learning, neural networks, natural language processing, and computer vision, which are essential for developing AI systems.

- The biggest driver for the application of AI in all industries, but especially in manufacturing, is the pending need to handle increasingly large and complex datasets.

- AI is transforming the manufacturing industry by streamlining production processes, transforming supply chain management, and enhancing efficiency.

- AI technologies, such as advanced sensors, embedded software, and robotics, are being applied to provide real-time visibility, predictive maintenance, and improved quality, aligning with Industry 4.0 concepts.

AI Fundamentals: Building Blocks of Artificial Intelligence

Before exploring the application of artificial intelligence in the manufacturing industry, let us first go back to basics. What forms the core of AI and its advanced technologies?

The answer lies in its foundational elements:

- Machine learning: a subset of AI, that involves learning autonomously from data and algorithms without the need for explicit programming. It mirrors human learning, where machines enhance their performance through experience.

- Neural networks: coupled with deep learning, these networks process sensory data, identify objects, and interpret spatial relationships. Essentially, a neural network is a system of interconnected units, akin to our brain’s network of neurons, that extract meaning from undefined data.

- Natural language processing: NLP techniques, enable AI systems to interpret both spoken words and text, making them capable of understanding and generating human languages.

- Computer vision: It allows AI systems to examine and interpret visual input, thus playing a pivotal role in their comprehension of the surroundings.

Each of these components plays a critical role in shaping the capabilities of AI systems, making them more similar to human intelligence.

With the advent of big data, AI has been able to learn, adapt, and improve its capabilities based on the vast amounts of information it consumes.

As AI continues to evolve, it is expected to contribute to building a comprehensive artificial intelligence ecosystem that leverages logical rules, probabilistic models, and sophisticated algorithms for reasoning and decision-making.

What challenges can manufacturers tackle with AI?

The manufacturing sector is intensely competitive, characterized by rapidly evolving markets and intricate systems with numerous components. In recent years manufacturers have had to deal with the ongoing rise of commodities prices, shortage of skilled workers, as well as rising workforce salaries. Supply chain disruptions were also an impediment to growth and left European manufacturers staling behind Asian competitors.

To overcome challenges, foster innovation and boost profitability, manufacturers must leverage all the benefits AI can provide. The biggest driver for the application of AI in all industries, but especially in manufacturing, is the pending need to handle increasingly large and complex datasets. AI can optimize process manufacturing by providing real-time visibility and predictive maintenance, which is crucial for both batch and continuous process manufacturing.

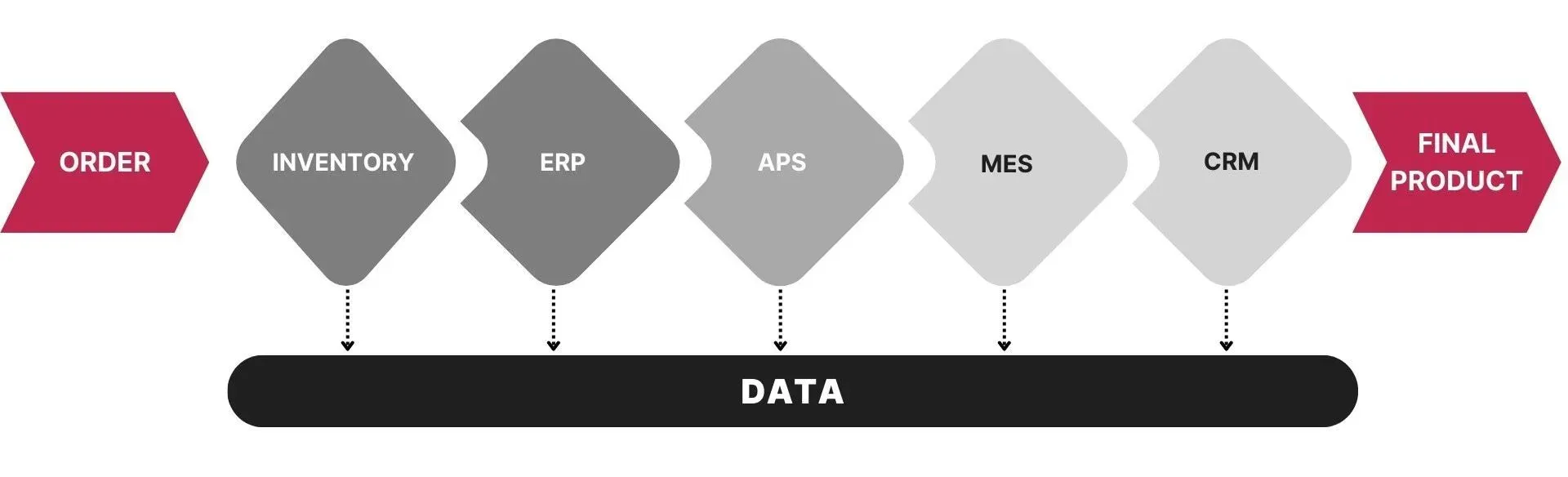

From vendor orders to customer deliveries, factories generate vast amounts of data at every value chain stage.

These large datasets hold valuable information that can be translated into actionable insights that inform the decision-making process. AI technologies offer to collect and process data on a level that will revolutionize the whole industry, from streamlining production processes to transforming supply chain management.

10 AI use cases in manufacturing

It is undeniable that manufacturers are heavily investing in artificial intelligence. Projections indicate that the global market of AI in manufacturing, valued at $3.2 billion in 2023, is expected to surge to $20.8 billion by 2028.

This is promoted by the large number of ways that AI can transform manufacturing processes.

Let's take a closer look at 10 key AI use cases in manufacturing:

Supply Chain Management

One very significant use case of AI in manufacturing is in supply chain management. AI in supply chain management enables the use of predictive analytics, improving inventory control, boosting demand forecasting accuracy, and simplifying logistics processes. Machine learning algorithms can examine historical data, recognize trends, and predict demand changes with precision. For example, an automotive parts manufacturer might utilize ML models to predict the demand for spare parts, enabling them to optimize inventory levels, cut costs, and enhance manufacturing output.

See how we helped Meraxis, the leading full-service provider of polymers and polymer-related solutions completely transform their procurement and sales processes.

Cobots

Unlike traditional robots, which need to be isolated, collaborative robots, also called cobots, are designed to operate safely in the same workspace as humans. They assist with tasks such as part picking, machinery operation, and conducting quality inspections, all of which boost productivity and efficiency. Cobots are highly adaptable and capable of handling a wide range of duties including gluing, welding, and greasing automotive parts, as well as picking and packaging products. The integration of AI-driven machine vision is crucial in enabling these capabilities.

Assembly Line Optimization

AI enhances assembly line optimization by increasing accuracy, efficiency, and flexibility. Machine learning algorithms analyze past and real-time data to improve workflows, reduce downtime, and enable predictive maintenance, much like the advancements seen with mass production techniques. AI-driven computer vision ensures product quality by detecting flaws. Intelligent automation adjusts production parameters based on demand, reducing waste and improving resource use. This continuous learning and adaptation make assembly lines data-driven and flexible, ultimately boosting output, reducing costs, and maintaining high manufacturing standards.

Predictive Maintenance

By leveraging AI to monitor and analyze data from machinery and the production process, manufacturers can detect abnormal patterns to forecast or prevent equipment failures. For instance, AI can evaluate data from vibration, thermal imaging, and oil analysis to determine machinery health. These insights help manufacturers correctly provision spare parts and consumables, as well as accurately predict downtime, aiding in production planning and related activities. This leads to enhanced productivity, cost efficiency, and equipment health. Additionally, generative AI can enhance value by scanning documents like maintenance logs and inspection manuals to deliver precise, actionable information for troubleshooting and maintenance tasks.

Product Development

Generative AI revolutionizes product conceptualization by analyzing market trends, identifying shifts in regulatory compliance, and summarizing product research and customer feedback. With these insights, product designers can innovate, enhance products, and ensure compliance by aligning specifications with relevant standards and regulations. The algorithms can rapidly produce innovative designs that surpass the capabilities of traditional methods. This allows manufacturers to optimize key product attributes such as safety, performance, aesthetics, and profitability by leveraging efficient manufacturing techniques.

Quality Control

AI revolutionizes testing and quality control processes by employing image recognition to automatically detect equipment damage, product defects, and issues with raw materials. By training AI models with images of both acceptable and flawed products, they can predict whether an item needs rework or should be discarded or recycled. Furthermore, AI’s analytical prowess can be harnessed to uncover improvement opportunities by identifying patterns in production data, incident reports, and customer complaints.

Simplified Documentation

A significant use of AI and machine learning in manufacturing is through robotic process automation (RPA) for paperwork automation. Manufacturing often entails extensive paperwork like purchase orders and quality control reports, which are traditionally handled manually, leading to delays and errors. By integrating conversational AI, companies can automate these tasks. Intelligent bots with AI can extract, classify, and enter data from documents into systems, streamlining operations and reducing inefficiencies.

Demand Forecasting

Utilizing artificial intelligence for demand prediction in manufacturing offers numerous advantages. Primarily, it empowers companies to make informed decisions by examining past sales data, market dynamics, and external influences. This enables them to foresee changes in demand and adapt their production plans accordingly, mitigating the chances of shortages or surplus inventory.

Order Management

Employing artificial intelligence in order management involves enhancing and simplifying the entire order processing procedure. AI analyzes historical data, customer preferences, and market patterns through machine learning algorithms to accurately predict demand. This enables automated order processing, inventory optimization, and real-time pricing adjustments. Furthermore, AI enhances fraud detection, reducing the risks associated with fraudulent orders. By automating repetitive tasks and providing data-driven insights, AI solutions in manufacturing enhance the efficiency of order management systems, expedite decision-making, and ensure a more agile and customer-focused approach to order fulfillment.

Connected Factories

Connected factories epitomize the integration of artificial intelligence into manufacturing processes, creating intelligent, interconnected environments. This networked setup enables efficient machine-to-machine communication, facilitating rapid adjustments to production schedules based on demand fluctuations. Predictive analytics bolster decision-making, ensuring smooth operations. In essence, AI-driven connected factories reduce expenses, enhance operational efficiency, and amplify productivity. By establishing adaptive manufacturing ecosystems manufacturers can swiftly adapt to evolving conditions using data-driven insights.

Overcoming barriers to AI adoption in manufacturing.

Even though there is no limit to the benefits and opportunities that AI can bring to manufacturers, companies are still approaching AI with caution.

Among the most significant challenges that manufacturers face in the adoption of AI technologies are:

Low-quality data:

The effectiveness of AI models depends on clean, high-quality datasets. Despite AI's advancements, many companies have fragmented data across isolated systems, requiring significant data engineering to clean and consolidate. Poor-quality data leads to inaccurate model outputs, regardless of algorithm sophistication.

To address this, companies should enhance their data pipelines and governance, conduct focused AI proofs of concept, and view AI implementation as a continuous, learning process.

Scarcity of skilled professionals

IBM’s Global AI Adoption Index 2023 reported that 33% of enterprises face limited in-house AI skills and expertise. AI projects need a diverse team, including data scientists, machine learning engineers, software architects, business intelligence analysts, and subject matter experts. Additionally, manufacturing will face a significant workforce shortage in the next decade as Baby Boomers retire.

AI Automation and AutoML 2.0 are essential technologies that can help bridge this skills gap and speed up digital transformation in manufacturing.

Concerns over AI trust and transparency

A major obstacle to widespread AI adoption is the complexity of the technology and the lack of trust manufacturers have in its capabilities. People without a data science background often struggle to understand data science and predictive modeling, lacking confidence in AI's abstract algorithms. Increasing transparency would help by providing information about the AI process, including the input data, chosen algorithms, and how predictions are made.

Traditionally, AI uses 'black box' models, but new data science methods offer more transparency throughout the AI pipeline. These methods explain the detailed process of transforming raw data into machine learning inputs (feature engineering) and how predictions are generated. By clarifying how prediction models work and the reasoning behind them, manufacturing organizations can build greater trust in the models and the business insights they produce.

Legacy system integration

Integration with existing infrastructure and legacy systems is another obstacle to AI adoption. Many manufacturing facilities operate on outdated technology platforms that may not be compatible with AI solutions. To overcome this barrier, manufacturers should prioritize interoperability when selecting AI tools and platforms. Additionally, investing in data integration solutions and middleware can facilitate seamless connectivity between AI systems and existing infrastructure. Collaborating with experienced technology partners can also provide valuable insights and support during the integration process.

Seizing the AI Opportunity with Intertec.

While these barriers are significant, they are minor compared to the risk of delaying AI adoption. Early adopters are continuously discovering new AI applications and widening their competitive edge.

Preparing organizations for this new era involves substantial effort, but the benefits and advantages gained from adopting AI are considerable.

Guidance from AI experts and specialized technology partners enables companies to effectively harness AI's value across the organization, ensuring proper implementation and seamless operations.

At Intertec, we pride ourselves on being a reliable tech partner to leading companies in the DACH region. Clients benefit from our extensive domain knowledge in industries such as manufacturing, digital commerce, and supply chain & logistics.

Leverage our applied AI expertise to increase efficiency and profits. Let's talk about your AI strategy.

Intertec

Book a Free Consultation

Trusted by leading businesses worldwide

Book a Free Consultation

You may also like

Towards Perfect ES Query Generation with Elastic-builder

Apr 09, 2020

Velimir Graorkoski

Elastic Builder To The Rescue

Apr 22, 2020

Velimir Graorkoski

Understanding the Most Effective Practices of Remote Working

May 19, 2020

Tanja Zlatanovska